Blowing, filling and screwing integrated machine integrates blowing, filling and capping functions on one equipment, suitable for PMRB series blow molding machine to realize the integrated control and production of multiple unit equipment, improve the production efficiency of the whole line, and reduce the investment cost and energy consumption And equipment maintenance costs.

| Reliability | Cost |

|---|---|

| run smoothly | Low maintenance cost |

| High integration | Low equipment investment |

| High mechanical performance | High efficiency of the whole line |

| Easy to maintain | Low plant investment |

The equipment required for the whole line configuration: water treatment, bottle blowing machine, filling machine, air duct conveying, labeling machine, paper wrapping machine, film wrapping machine, unpacking machine, packing machine, sealing machine, looping machine, code Stacker, depalletizer

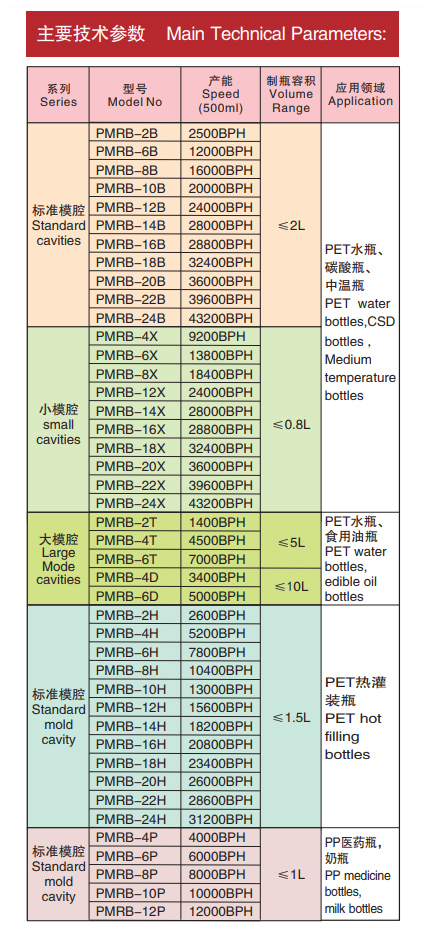

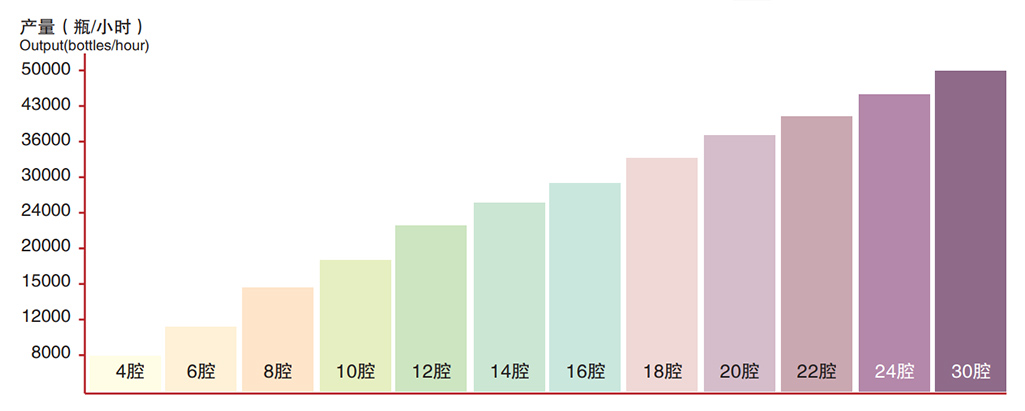

Collecting a number of national patents, absorbing the most advanced bottle-making technology at home and abroad, and integrating it into the PMRB series of automatic high-speed rotary bottle blowing machines. The perfect design, exquisite structure, and international high-end electrical control system make the performance of the whole machine extremely stable. The whole production process: feeding, billet management, billet feeding, heating, transmission, stretching, air blowing, cooling, and finished product conveying are all automatically monitored by computer without manual assistance, high automation, low production cost, and the yield rate is as high as 99.7 %. Become the first choice of domestic famous beverage packaging companies.

It is suitable for the production of pure water bottles, mineral water bottles, beverage bottles, carbonated soda bottles, high temperature hot filling bottles, edible oil bottles, large medical infusion PP medicine bottles and other industries with large output and high quality requirements. Become the first choice of famous beverage packaging companies at home and abroad.

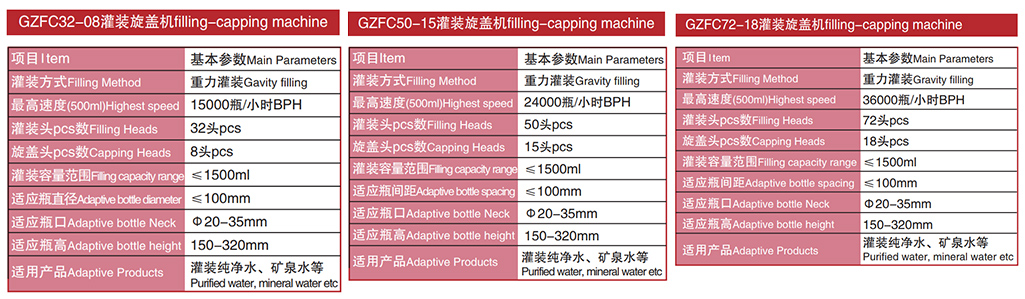

Guangdong Guozhu Bottle Blowing Equipment Co., Ltd.'s PET bottle filling and supporting equipment covers GZDRFC flushing, filling and capping integrated machine, GZRFC series flushing, filling and capping integrated machine, GZBFC series blowing, filling and capping integrated machine and other combination models. Creative design, excellent selection of materials, precision machining, ingenious assembly, strict debugging, achieving first-class quality, made by National Pearl!

PET bottle water/mineral water filling and capping integrated machine adopts star wheel card bottle feeding, mechanical control filling valve, adjustable torque mechanical capping head and other technologies to achieve docking with bottle blowing, bottle feeding, filling, capping, Processes such as bottle-out, no-bottle and no-closure. The electrical system adopts world-renowned brands (such as ROCKWELL AB, SEW, FESTO, SMC, INOXPA, etc.). All parts in contact with filling materials are made of high-quality stainless steel or food-grade materials. Guozhu filling equipment is highly intelligent, simple to operate, high stability, low failure rate, and internationally leading product quality.